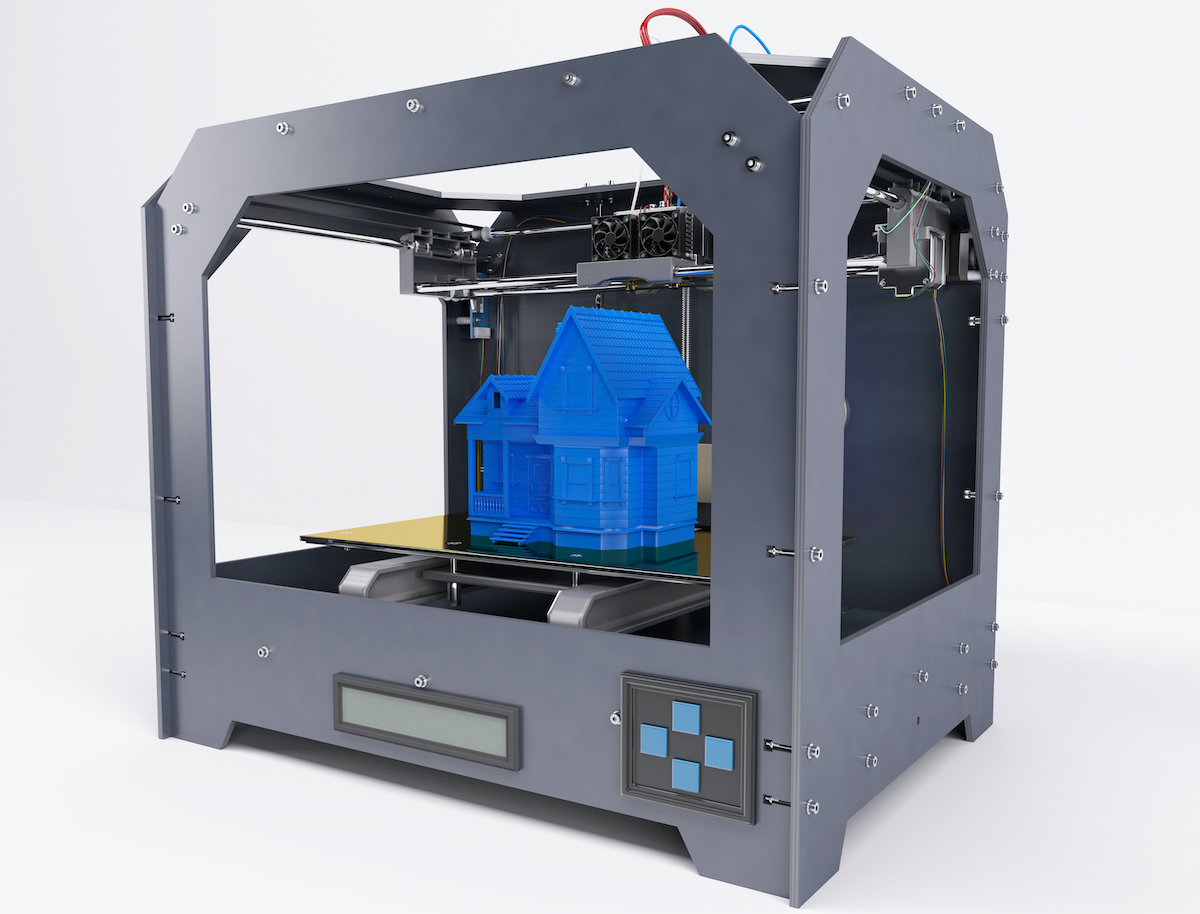

Big challenges face our society and our planet, none bigger or more pressing than climate change. A ray of hope is how innovative new technologies are tackling a number of these challenges simultaneously. In the housing sector, the 3D-printing process, without much publicity, is launching a revolution in construction materials and methods that are addressing affordability, energy-efficiency, durability, and beauty while erecting structures in record time and at scale.

The software, robotics, and new mixes of materials are technically complex but once the large printers, equipped with robotic arms that travel on rails, are set up, the process is simple. Nozzles at the ends of the robotic arms extrude environmentally friendly concrete mixes, plastics, hemp, mud, wood fibers, and other materials in a layering sequence to create solid, three-dimensional walls. Large sections of the building are printed and then assembled. Tech firms and architects are teaming up to produce designs that incorporate undulating curves that would be extremely time-consuming and prohibitively expensive to create using traditional building practices.

Jason Ballard, CEO of one of these pioneering tech firms, says, “With 3D printing, you not only have a continuous thermal envelope, high thermal mass, and near zero waste, but you also have speed, a much broader design palette, next-level resiliency, and the possibility of a quantum leap in affordability. This isn’t 10 percent better; it’s 10 times better.”

This type of construction is being employed in the Netherlands, Mexico, Canada, the U.S., and in areas impacted by natural or man-made disasters where quick rebuilding is urgent. These houses are built to withstand hurricanes and earthquakes. Entire communities are being designed and constructed; sometimes the printing is on-site and sometimes close by. Lennar Construction, one of the country’s largest builders, is building a 100-unit 3D-printed home development in Texas. Austin, Texas, has become a hub of robotic construction in this country. For example, it is turning out 400-square-foot homes to house 480 homeless people, or 40 percent of its street dwellers. The cost is $4,000 per unit. Printing time for an entire home varies between 24 hours and a week and a half, the longer period being for larger custom homes.

Biophilic design, the recent term for increasing occupants’ connectivity to the natural world, is being embraced in most of these ventures. The mechanical nature of the production process may give the impression of uniformity and starkness, but the irregularities and imperfections of the striations have led some to compare the homes to adobe architecture. Similarly, the softer curves often harmonize with nature. Carefully thought-out, intricately designed print paths accommodate and hide high-performance mechanicals.

The potential of 3D-printed housing embraces beauty, livability, economy, and resource efficiency while cutting construction time to a fraction of that required by traditional building methods. How quickly will it move to mainstream?

Support the Santa Barbara Independent through a long-term or a single contribution.

on Google

on Google